|

National free service hotline 137-0622-7963 Telephone:0512-58140198 Fax:0512-58299151 mailbox:jzh@dhjx.com.cn Website:www.suchcuteguys.com Foreign trade department: Mrs yu: 15150256382 Mail:keith@junmachina.com |

|

address: No. 80, Zhangjiagang City, Jiangsu City Road, No. |

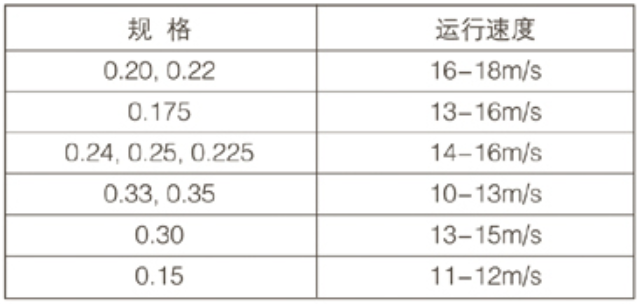

Diameter of coil in :0.8-1.9mm

Diameter of coil out:0.15-0.35mm

Drawing rounds: 23 rounds

Drawing speed: 18m/s at maximum operating speed, speeds available in normal operating mode are shown in followin table.

Spool structure

5.1 Split type 4-step pulley

5.2 Size of step pulley: norminal diameter: ±0.5mm

6. Mechnical speed ratio: 1-20 rounds 14.5%, 21 rounds 6.3%

7.Pay-off

7.1 Pay-off spool: spool of Model 800 in general (or upon request of customer)

7.2 Pay-off form: pneumatic ejecting passive pay-off, regulation of damping tension under pneumatic control

7.3 Coil out wheel is designed as wobble wheel to reduce probility of wire scractching

8.Take-up

8.1 Take up motor: 2.2Kw VF motor. (Capacity of the motor is subject to specifications of take-up spool defined by the customer)

8.2 Take-up is megnetic based (with spool subjects to customer requirement, due consideration shall be given to specifications of spool in this approach)

8.3 Take-up tension control: adjustable counterweight.

8.4 Take-up brake: pneumatic brake.

9. Winding displacement:

Winding displacement is controlled by 0.75Kw servo motor, achieving even and flat winding free from problems such as entrapped wire, disordered wire or missed wire. Displacement pitch may be enlarged manually.

10.Time set for start up and shut down can be adjusted in range from 30s to 70s; time set for emergency stop is less than 5s.

11.Drive motor: ACVF, Power: 22Kw or 30kw (subject to specifications of specific product)

12.Electrical control: PLC control, multi-function automatic protection.

13.Step pulley surface treatment: WC spray coated up to HRC60-62, warranty period for step pulleys is 1.5 years.

14.Mold size: @28*15, mold case for three-point adjusting.

15. Lubrication and cooling: immersed circulation cooling

16.Lubrication case capacity: 750L

1. Main rack is we lded and followed with aging treatment.

2.SKF product is selected for main shaft bearing and NSK for other remaining bearings. Surface jumping of the stepped wheel is controlled to be less than 0.05.

3.Angle-adjustable cross thread guide roller for wire over is installed at coil in port to minimize scratches.

4.Spools in diameter of 300 or more is designed with horizontal take-up rack vibration aging treated

5.Water tank is equipped with stainless steel shell to reduce heat discharge of lubricant.

6.Ring adjuster is designed in principle of 3 points adjustment, namely, to fix at one point while adjust at the other two points, which is easy for operation without necessity for changing the ring.

7.PLC control, multi-function automatic protection and wire breaking protection.

8.Able to indicate parameters of equipment including product specifications, take-up speed, take-up meters, lubricant temperature, operating time of the shift on duty etc.

9. Meter measuring is precise up to 1‰, with correction factor, which guarantee consistency of precision range of all related machines.

10. Energy saving high efficient motor is adopted.